A KAIST research team may have found a solution to the shortage of protective masks amidst the global COVID-19 crisis.

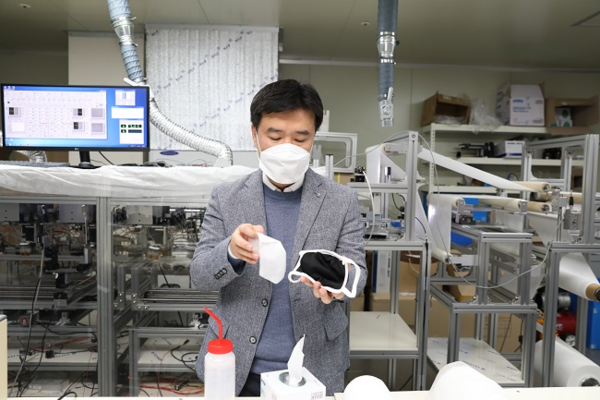

On March 16, a research team led by Professor Il-Doo Kim, from the Department of Materials Science and Engineering, announced that they have developed a novel non-woven nano-filter material that may put an end to the mask shortage. A face mask produced from this material can be washed and disinfected while maintaining its excellent filtering efficiency.

Conventional mask filters use electrostatic methods to block particles, so their efficiency wears off as the static energy on the surface gradually disappears. Additionally, electrostatic function disappears upon contact with water, making it impossible to wash and reuse the mask.

In contrast, Professor Kim’s filter is produced by crossing and aligning fine nanofibers to create small air holes that block viruses while allowing easy breathing. In other words, the filter does not rely on static electricity, but provides a physical barrier instead. The material was proved to preserve more than 94% of its filtration ability after 20 hand-washings with soap, and is safe to use for up to a month. Moreover, it showed no deformations in its nano-fiber structure after soaking in ethanol for three hours and withstood 4,000 mechanical crumples and stretches.

Professor Kim established a start-up company under the name of “Kim Il-Doo Research Institute” in February 2019. Initially, he intended to produce masks for preventing fine dust inhalation. The company owns a production facility not far from the KAIST main campus in Daejeon, and can produce seven meters of the membrane per hour — enough to make 1,500 masks a day. Professor Kim has plans to expand the facility to relieve the crisis caused by COVID-19 and mask shortages both in Korea and abroad. Unfortunately, there is still a way to go: the company needs more investments and a certification from the Ministry of Food and Drug Safety before its product can hit the shelves. The market price of the nano-filter itself is a modest 2,000 KRW; the cost of a cotton mask is added if they are bought together.

The nano-masks could also solve the growing environmental pollution caused by improper disposal of single-use masks. “If we assume that more than 10 million masks per day and 300 million masks per month are discarded in Korea, it will be a breakthrough product from an environmental perspective,” — the professor says.