Fabrication technology that may enable a more economical production of liquid-repellent surfaces was recently developed by a research team led by Professor Shin-Hyun Kim and Professor Hee Tak Kim from the Department of Chemical and Biomolecular Engineering.

Superomniphobic surfaces are structures that possess extreme repellency to virtually all liquids, capable of maintaining non-wetting states against both high and low surface tension liquids. Mushroom-head-shaped textures help retain the slip effect and dryness of the surface by increasing its hydrophobic stability. Hence, these surfaces are useful for shielding materials from the effects of chemicals. Current protocols for the fabrication of these structures are limited in their practicality; they are tedious, expensive, and delicate, not to mention that rigid and costly silicon wafers are used as the main material, urging the need for significant improvements.

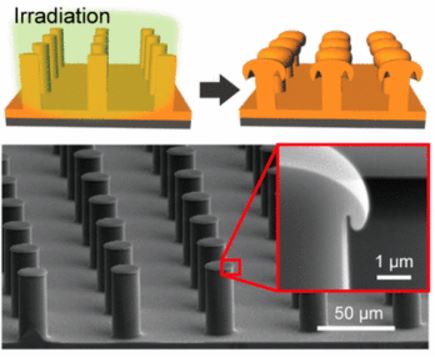

The joint research team devised a novel approach to creating such nano-structured surfaces that yield superomniphobicity through localized photo-fluidization of azopolymers, azobenzene-containing polymers used in thin films that have specialized optical properties. Photo-fluidization refers to light induced plasticization of the surface due to efficient trans-cis cycling of the polymers. This technique was utilized by the team to modify the nanogeometry of micropillars on the top surface layer of the azopolymers to one that is doubly re-entrant. This makes the micropillars point inwards and have enhanced resistance to liquid infiltration.

Professor Shin-Hyun Kim mentioned, “The doubly re-entrant geometry design was inspired by the skin structure of springtails, insects dwelling in soil that breathe through their skin,” expressing his opinion that humans can learn and adapt from nature to create new, original engineering designs. Professor Hee Tak Kim enunciated the new technology’s diverse application potentials by adding, “Not only does the novel photo-fluidization technology produce superior superomniphobic surfaces, but it also has numerous practical advantages in terms of fab-procedures and material flexibility.”

It is anticipated that the team’s method will contribute to the cost-effective manufacturing of flexible and sturdy superomniphobic surfaces for use in stain-free fabrics, non-biofouling medical tubing, and corrosion-free surfaces.