With the prolonged COVID-19 situation, masks have become indispensable. As the search for better quality mask filters continues, polymer micro and nanofiber webs have emerged as a prospective material. Whereas the currently prevalent filters are difficult to breathe in due to their thickness and lose efficiency in humid conditions as they rely on static electricity, filters based on polymer nanofibers are extremely thin and have strong droplet-blocking ability, mechanically filtering out more than 90% of particulate matter and pathogens. Furthermore, they can be washed and reused without compromising on efficiency. These benefits have led to an increase in the demand for the material.

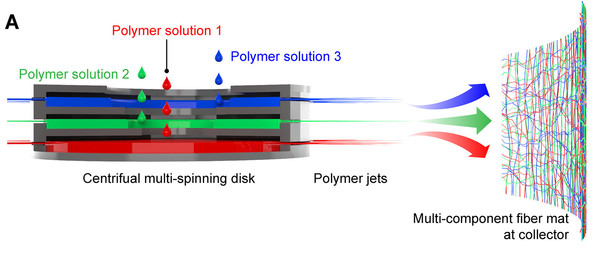

On March 23, a research team led by Professor Do Hyun Kim from the Department of Chemical and Biomolecular Engineering announced the development of a novel manufacturing process using centrifugation that allows for mass-production of these micro and nanofibers. The devised centrifugal multispinning system rotates polymer solutions such as polystyrene, poly(methyl methacrylate), and polyvinylpyrrolidone (PVP) to weave out fibers. The sectioning of the rotating disk into three subdisks increased the production rate to approximately 300% faster than previously possible, achieving up to 25 grams of 500-nanometer fibers per hour, an amount equivalent to nearly 30 KF94 mask filters. Experiments conducted by the team also revealed that this production rate increased proportionally with an increase in the number of subdisks. The manufactured prototype filters showed high standards of dust collection, inhalation pressure, and droplet-blocking ability similar to the level of KF80 or KF94 masks.

The paper detailing the results of the research, titled “Large Scale Centrifugal Multispinning Production of Polymer Micro and Nanofibers for Mask Filter Application with a Potential of Cospinning Mixed Multicomponent Fibers,” was published on the front cover of the March issue of the ACS Macro Letters journal. First author Byeong Eun Kwak remarked that centrifugal methods have clear advantages in terms of cost, efficiency, and safety in comparison to established electrospinning method, stating, “It is anticipated that the unit cost of producing nano-filters will be significantly reduced if this centrifugal system is amplified to an industrial scale.” In addition to being able to produce large quantities of fiber, the technology also makes it possible to manufacture filters combining multiple types of polymer fibers, such that the properties of the product can be controlled. This may also be applied to textile industries. Once the biological safety of nano-substances is verified, a wider application of nanofiber filters can be expected.