The acceleration of climate change calls for an increasing urgency for research on renewable energy harvesting systems. A collaborative research team led by Professor Inkyu Park and Professor Il-Kwon Oh from the Department of Mechanical Engineering, and Dr. Jun-Ho Jeong from Korea Institute of Machinery and Materials (KIMM) announced the successful development of an eco-friendly all-recyclable triboelectric nanogenerator (AR-TENG) that can harvest marine energy to power ocean monitoring systems. The study, in which PhD students Junseong Ahn and Ji-Seok Kim participated as co-first authors, was published on the back cover of Advanced Energy Materials in August under the title “All-Recyclable Triboelectric Nanogenerator for Sustainable Ocean Monitoring Systems”. In an interview with The KAIST Herald, Ahn provided us with insights into the team’s motivations, and the nature and direction of their research.

Could you explain your research to our readers?

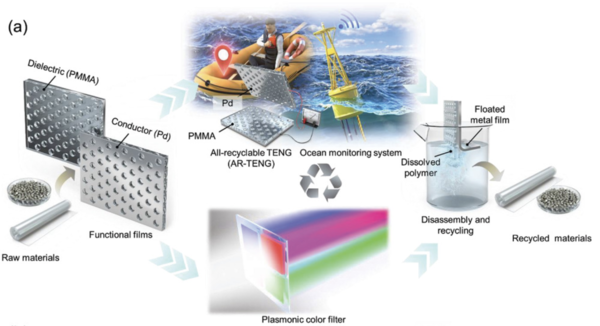

Our study is about the development of an eco-friendly AR-TENG that exhibits high performance and mechanochemical stability in marine environments. Triboelectric nanogenerators (TENG) are devices that can harvest renewable energy. The entire AR-TENG, including the thermoplastic polymer and the noble metal electrode, is constructed with recyclable materials. We believe its ability to be reused as various optical devices such as plasmonic color filters after use in marine harvesting systems will help solve global energy issues and environmental pollution. Additionally, we demonstrated the applicability of AR-TENG by using the harvested marine energy to charge a battery and run an electronic device integrated with a wireless communication module that monitors different ocean conditions (pH, salinity, temperature, [and] oil leakage) and detects any emergencies at the sea.

How is AR-TENG different from other recyclable TENGs in its structure and function?

In order to create a recyclable TENG, we aimed to construct the most simplified structure and use the optimal material that would complement [the simple structure]. Unlike the complex structure of most existing TENGs which consist of several layers of materials, we used a bilayer structure with only two materials — polymethyl methacrylate (PMMA), a dielectric insulator, and palladium (Pd), which can simultaneously be used as a contact metal and as an electrode. To ensure that the simple structure of AR-TENG does not compromise its performance, we carried out surface nanopatterning and developed an optimal nanohole pattern that provides mechanical stability.

Could you briefly explain the working mechanism behind AR-TENG-based energy harvesting systems?

The buoy-type system that floats on the surface of the sea receives vertical mechanical vibrations from waves. We implemented a spring-mass system in which repeated contact-separation of PMMA and Pd is induced when mechanical vibration is applied. The triboelectric energy that occurs from the recurring contact-separation is harvested through a circuit and stored in the battery.

How did you test the mechanochemical stability and energy harvesting performance of AR-TENG?

We tested the mechanical stability of AR-TENG by conducting a total of 1,000,000 cyclic tests, and tested its chemical stability by immersing it into seawater for more than a day [before] operating the device again. When we compared the surface observations through scanning electron microscope (SEM) images and energy harvesting characteristics before and after [the stability tests], we found no changes in the general characteristics of the device.

Are there any drawbacks to using acetone as a solvent to recycle AR-TENG?

Acetone is classified as a green solvent; however, some research reports its toxicity. Other literature also suggests that the recycling of PMMA can release toxic chemicals. Therefore, there are limitations in that the recycling of AR-TENG is not yet a completely environmentally-friendly process.

Do you intend to conduct any follow-up studies? How do you think your study could be improved further?

I believe further research should be conducted in many aspects because existing devices from current research on environmentally-friendly TENGs are only partly recyclable and cause environmental pollution upon dissociation. We plan to conduct a follow-up study on nanopatterning wood-based materials, which are much more eco-friendly than PMMA, to achieve higher performance and more benefits [from an environmental perspective]. I hope there will be more opportunities for us to introduce our follow-up studies in the future.